Process of Handmade pottery production.

1. Starting Handmade pottery from soil preparation. The clay soil as the sun set to the clay Dankwian 2 parts sand and 1 part water data used to sun dry And ground thoroughly. Leading to fermentation of the soil.

2. Fermented soil from the sun. Prepared to take. And well prepared the soil is 50 multiplied by 150 cm into the clay before a Dankwian the bottom and the other grounded Sing a middle part and the clay down on the wagon again Dan, take a rest water. well enough in flooded soil. The pond to leave a day for 1 night leads to a process of clay.

3. The clay soil used to make the fermented mash to combine then be rolled. Clay machine. Prepare the soil will come out lumpy. Handmade pottery

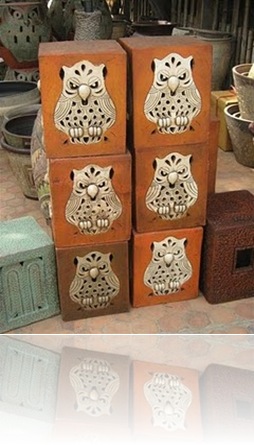

When the soil from the ground and then roll formed according to the nature of which will be seen that work. At the port of the cart is a unique work of my own in that does not work, type known as a copy of the image for a container to take up to 45 days, or it may be more or less time depending on work produced. Handmade pottery

Then step into the fire. Will have to churn That has been dry enough spin is already formed or are about 1-2 weeks to bring down the incinerator. If it brings down while the mold is still damp can cause breakage is not worth my money to spend.

In a Handmade pottery oven whenever required to provide the proper heat. Depending on size, big or small pottery in order to determine the number of entries. The use of wood burning or wood burning temperature of 980 -1050 degrees Celsius, which will come out in the form of Terracotta burn time of 3-4 days.

11/22/2010

11/22/2010

Pottery

Pottery

0 comments:

Post a Comment